Quality control (QC) and assurance (QA) are systems designed to ensure that garments meet brand specifications, performance expectations, and safety regulations. QC includes inspection checkpoints during and after production, while QA focuses on preventive measures during development and planning.

Common QC tests include dimensional accuracy, seam strength, colorfastness, and appearance. QA may involve risk assessment, defect prevention training, and standard setting across factories.

Achieving high quality requires a systematic approach. Brands must define quality benchmarks, use clear tech packs, and train factory workers. Third-party labs and in-line inspections are critical for catching defects early.

Brands should adopt AQL (Acceptable Quality Level) standards to statistically sample and approve large batches. QA processes like root cause analysis, CAPA (Corrective and Preventive Action), and continuous improvement programs ensure long-term product consistency.

Eton’s QC teams are trained to execute multi-stage inspections at the cutting, stitching, finishing, and packing stages. We deploy digital inspection tools and standardized forms to record and share results with clients in real time.

Our QA protocols are preventive. Before bulk production begins, we evaluate risks and run trial lines. We also maintain a zero-tolerance policy on critical defects and align inspections with client-specific expectations.

Our track record with global brands demonstrates our ability to deliver consistent quality across diverse product categories and factory locations.

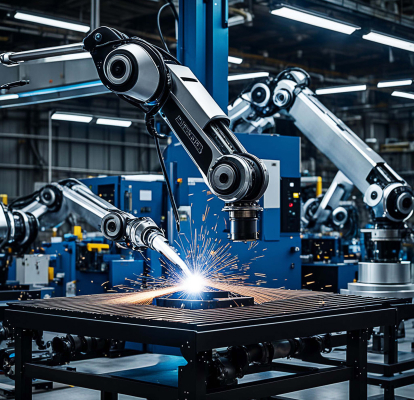

Robotics streamline complex tasks, reducing production time and minimizing downtime, which leads to higher output and faster delivery.

Robotics streamline complex tasks, reducing production time and minimizing downtime, which leads to higher output and faster delivery.

Robotics streamline complex tasks, reducing production time and minimizing downtime, which leads to higher output and faster delivery.

Robotics streamline complex tasks, reducing production time and minimizing downtime, which leads to higher output and faster delivery.

Our Industrial Automation and Robotics planning and strategy services focus on designing tailored automation solutions that align with your business goals.

We implement rigorous quality control measures at every stage of production, ensuring consistency and high standards.

We implement rigorous quality control measures at every stage of production, ensuring consistency and high standards.

We implement rigorous quality control measures at every stage of production, ensuring consistency and high standards.

We implement rigorous quality control measures at every stage of production, ensuring consistency and high standards.

We implement rigorous quality control measures at every stage of production, ensuring consistency and high standards.

Let’s build the future together. Join forces with Eton Group today and unlock cutting-edge manufacturing and supply chain solutions that not only drive innovation but also create lasting value, sustainable impact, and long-term success for your brand, your customers, and the generations to come.

A member of the Eton Group