Material sourcing in the apparel industry is the process of identifying, evaluating, and securing the fabrics, trims, labels, and accessories needed for garment production. This stage is crucial because the quality, sustainability, and performance of sourced materials directly impact the final product. In today’s fashion ecosystem, sourcing is no longer just about availability and cost—it also involves traceability, eco-certifications, compliance with chemical safety standards, and ethical labor practices.

Suppliers range from large fabric mills to small-scale trim producers across various global markets. The sourcing process begins with technical specifications defined during product development, followed by vendor selection, material testing, sample approvals, and bulk purchasing. To remain competitive, brands often work with multiple suppliers to diversify risk and ensure continuity.

Successful material sourcing requires a combination of technical knowledge, supplier relationships, and digital systems. Brands must first understand fabric constructions, weights, finishes, and performance attributes to specify the right textiles. Testing labs ensure material durability, colorfastness, and wash performance.

Sustainability is a growing concern. Leading fashion brands now prioritize materials with certifications such as OEKO-TEX, GOTS (Global Organic Textile Standard), and recycled fiber origins. It’s essential to build a network of certified suppliers and continually monitor for compliance and innovation.

Using digital sourcing platforms allows brands to compare pricing, lead times, and sustainability scores across multiple suppliers. Scenario planning also helps align material selection with design intent and margin targets.

Eton’s sourcing capability is built on decades of trusted partnerships with certified textile suppliers across Asia, Europe, and Africa. We offer clients access to an extensive fabric library—including organic cotton, performance knits, and technical outerwear materials—ensuring design flexibility and on-time availability.

Our sourcing teams conduct regular mill audits and fabric testing to ensure consistency and safety. We proactively guide clients through sustainable material options that meet their brand values and compliance requirements.

Through digital coordination and regional sourcing hubs, we align materials procurement with production timelines, eliminating delays and reducing excess inventory. Our sourcing strategy not only supports design creativity but also mitigates cost and supply chain risk.

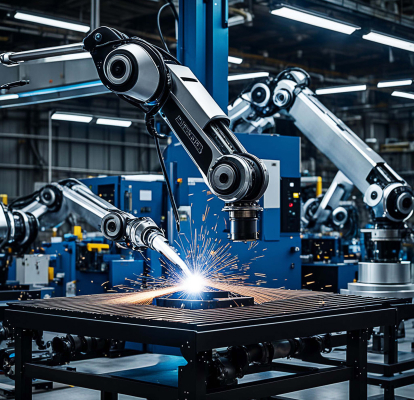

Robotics streamline complex tasks, reducing production time and minimizing downtime, which leads to higher output and faster delivery.

Robotics streamline complex tasks, reducing production time and minimizing downtime, which leads to higher output and faster delivery.

Robotics streamline complex tasks, reducing production time and minimizing downtime, which leads to higher output and faster delivery.

Robotics streamline complex tasks, reducing production time and minimizing downtime, which leads to higher output and faster delivery.

Our Industrial Automation and Robotics planning and strategy services focus on designing tailored automation solutions that align with your business goals.

We implement rigorous quality control measures at every stage of production, ensuring consistency and high standards.

We implement rigorous quality control measures at every stage of production, ensuring consistency and high standards.

We implement rigorous quality control measures at every stage of production, ensuring consistency and high standards.

We implement rigorous quality control measures at every stage of production, ensuring consistency and high standards.

We implement rigorous quality control measures at every stage of production, ensuring consistency and high standards.

Let’s build the future together. Join forces with Eton Group today and unlock cutting-edge manufacturing and supply chain solutions that not only drive innovation but also create lasting value, sustainable impact, and long-term success for your brand, your customers, and the generations to come.

A member of the Eton Group